What is an NCR in Construction

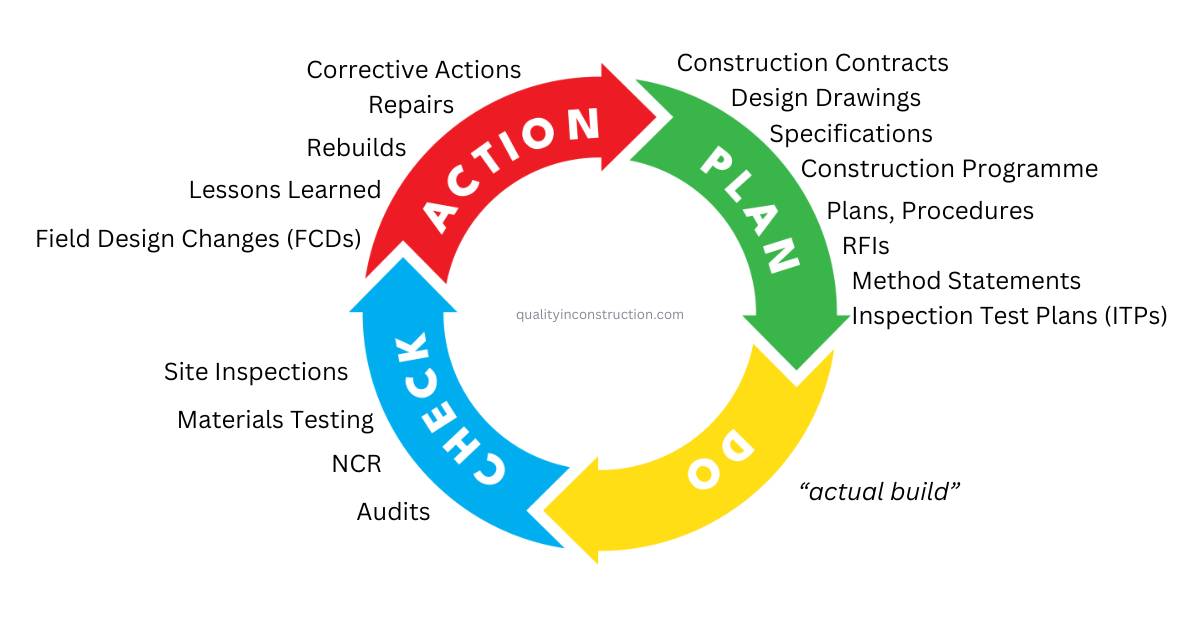

NCR is one of the most fundamental tools for Quality Management and Quality Control in modern Construction Projects. Because it actually has a very bad reputation as an acronym in the industry, it is important to understand how it can actually be used in construction today and how a construction project and a construction company can benefit massively from its use.

What does NCR stand for in construction?

NCR in construction stands for NonConformance Report and it is a report that is used to capture, trace and record the repair process of issues that occurred in a construction site or generally in a construction project.

We can simply describe it as a Report that outlines:

- What went wrong (this is the “nonconformity”)

- Why it went wrong (Root Cause)

- What happened to mitigate the issue immediately (correction)

- What can we do in order to avoid that from happening again (corrective action).

Bear in mind that if a construction project or a construction company needs to be ISO 9001 Certified then it is a requirement to have and implement a NonConformance Procedure or Process, otherwise it cannot simply get certified.

Also, please note that in construction there can be 2 different types of nonconformities:

- Actual product nonconformities (something that affected the project/building itself e.g. material failure)

- Procedural nonconformities (something that did not have an immediate effect on the project but has been raised because a procedure was not followed e.g. a document has not been approved by the Client)

Why the NCR is needed in construction

As I mentioned previously, NCRs are extremely valuable tools in the construction industry because are nowadays the main tools to learn from the mistakes of the past and are the main “vehicles” towards the continuous improvement target of an ISO9001 certified organization/company.

The construction industry has a very bad reputation for repeating the same mistakes without really “carrying” that much. That wouldn’t actually be a problem if it was not costing real money that can literally bring a construction company and a project to its complete closure and shut down.

Stages of an NCR in Construction

Managing NCRs in a construction project can be very challenging because (especially in bigger projects) there are lots of stakeholders, designers, Clients, Suppliers and even contractors and subcontractors that may be involved in an issue.

To be honest, every construction company and every construction has a different NCR Process and the procedure really depends on the size and the complexity of a project, but in general, the stages of an NCR in construction can be as follows:

- Identification: this is where all the details of the issue must be recorded with as much evidence (documents, photos, videos, records) as possible. In this stage, it is also extremely important to mention the requirements that have not been followed with as much details and references as possible.

- Root Cause: this is a typical Root Cause Analysis that is an exercise that must happen in every NCR that occurs and must also be recorded on the NCR form itself

- Remedy: this is the stage where all the corrections and the corrective actions are proposed, approved and recorded (before they are actually done); the difference between the Correction and the Corrective Action is very important as the Correction is something that is applied to fix the issue, but the Corrective Action must be taken to avoid it from happening again in the future (which is also the most important part)

- Closure: this is the stage where the closure of the NCR happens. Evidence must be provided after both the Correction and the Corrective Action have been implemented (in many cases it can take months or even years) and it would be good if everything is signed off finally by a high authority person in the project/company.

Typical NCR in Construction

Many things can go wrong in a construction project or a company and this list can literally be endless, but to my experience, almost all quality NCRs that I have ever seen belong to one of the following categories:

- Something was not built as per the approved Design Drawings, or it’s not within the tolerances specified in the design drawings

- The approved methodology (Method Statement) was not followed during the construction

- The approved Inspection and Test Plan (ITP) was not followed

- Any other approved documentation was not followed (Quality Procedures, instruction from the Client, RFI etc)

- A different material than the approved one was used on-site

- A test on a material or something else failed

- A Design failure (the design was followed but it was originally wrong)

- There is no available documentation to cover an activity (Method Statements, Design Drawings, ITPs, Risk Assessments etc), or the existing documents do not describe the activity sufficiently

- The requirements for specific items were not precise and an RFI or Design Change was never issued

- A Contractual or Statutory requirement was not followed

Who decides what is a nonconformity (or non-conformance) on site?

An NCR (or just a nonconformity) shouldn’t be a decision of one person or entity.

It has to be a fact with no debate at all.

If everything in terms of design, requirements and specs are crystal clear since day 1 of a Project, then there shouldn’t be any discussion at all.

However, dodgy contracts, last-minute requests, unfortunate conditions, bad planning, and poor risk analysis can lead to endless discussions and arguments between contractors, designers, project managers, and clients during the construction phase. This is not an ideal situation.

As a result, Contractors are pretty resistant to raising/opening a NonConformance (NCR) because

- There might be severe financial implications. It’s not uncommon that a nonconformity can lead to significant claims and compensation events.

- There is a “blame” culture around the NCRs. People don’t like it when they have to recognize that they didn’t do their job well (especially if we are talking about construction people with many years of experience on their shoulders). An NCR is actually admitting that (more or less) they didn’t do what they should have done and that they may have to correct it or even change the way they used to do things on site.

- A nonconformity might be blocking the progress of the works especially when it is directly linked with the next construction stage and it has to be closed before moving on. This might be catastrophic for the Contractor if we are talking about an activity that is on the critical path.

- Depending on the Project, there might be quite a lot of administrative work to be done for every NCR. Many Clients require an in-depth root cause analysis, documents and forms to be completed and objective evidence to be attached for each NCR. During the rush of the construction phase and when the clock is ticking, all of these may sound as a “luxury” and more like a paperwork exercise that everyone wants to avoid.

CONCLUSION

NCRs in construction are some of the most important tools to manage quality control and have a record for future reference in terms of learning a lesson in order to avoid similar mistakes and lapses. It is also a requirement of the ISO 9001 standard and a fundamental tool for continuous improvement for any construction company. It is also true that sometimes can be a burden and create unnecessary friction between the different stakeholders of a construction project.

Member discussion