One of the main difficulties and differences between the construction industry compared to the typical controlled manufacturing environment, is the way things are measured and monitored.

Get Your Free ITP Template

Download the Inspection & Test Plan Template that has been used across 1000's of construction projects all over the world.

If you are working in a quality role in construction, then you know the inherent difficulties on how to measure quality in construction projects and how challenging it can be, so it comes as no surprise the fact that construction companies and organizations don’t do it properly or not at all.

One of the main difficulties and differences between the construction industry compared to the typical controlled manufacturing environment, is the way things are measured and monitoredWhat the ISO 9001 Standard says about Measuring Quality.

Thankfully, ISO 9001 – 2015 defines exactly what needs to be measured in any ISO 9001 certified organization, so our guide should be just that.

So, this is what the Standard says about what needs to be measured and monitored (cl.9.1.3):

– conformity of products and services;

– the degree of customer satisfaction;

– the performance and effectiveness of the quality management system;

– if planning has been implemented effectively;

– the effectiveness of actions taken to address risks and opportunities;

– the performance of external providers;

– the need for improvements to the quality management system.

So, it should really be straightforward to measure quality in construction projects, right?

Unfortunately, it is not that easy or manageable in my opinion, because there are a million parameters and stakeholders in most of the cases, while every project is a unique and complex environment like no other.

However, modern quality management in construction offers plenty of tools to streamline and make the whole process more practical for organizations that are striving for improvement and Client Satisfaction overall.

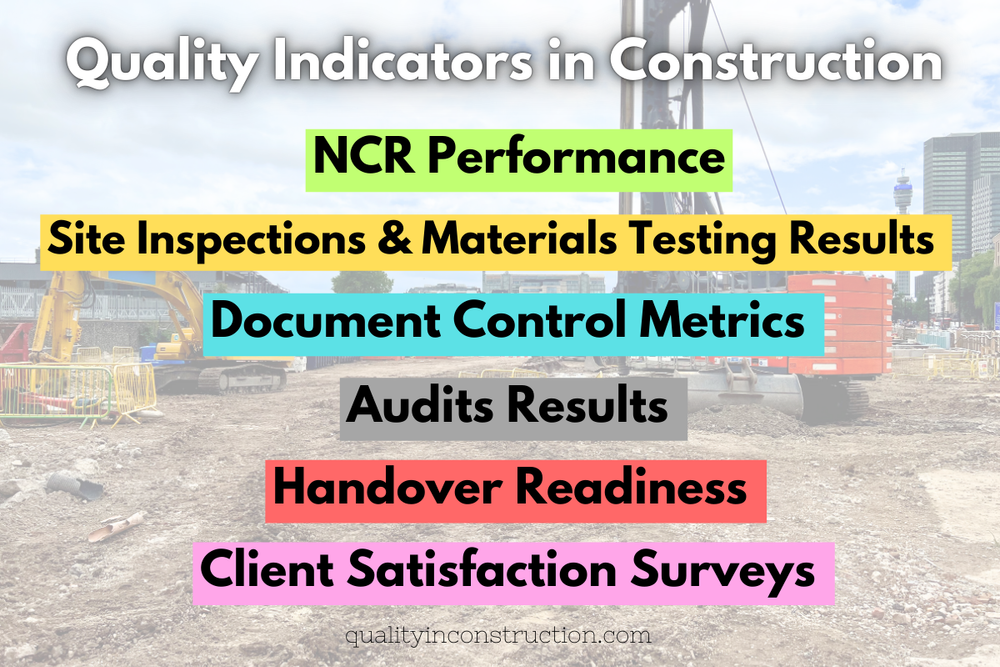

How To Measure Quality in Construction

In an attempt to “translate” the Standard’s wordings (as seen above) and speaking from my 20 years of experience in construction, here is a list of things you can measure in a construction project that could work towards continuous improvement but also stay practical and realistic at the same time:

1. NCRs in Construction

Measuring and monitoring Nonconformances in a construction project is the ultimate Quality Control tool in an uncontrolled environment, such as a construction site. Nowadays, every respectable construction project, anywhere on the planet, should have a way of controlling, reporting and monitoring the Nonconformities that occur on site and that are directly or indirectly affecting the final product (which is the project that is being built).

So, what exactly can be measured with NCRs in a construction project and how?

- The first step is obviously to have a proper and robust NCR Management Process in place for the project, which will basically describe how these are controlled and managed; it goes without saying that this must be fully supported by the Senior Management

- An NCR Form must be in place (or even software) in order to make sure all issues are recorded with as much details as possible

- An NCR Follow Up Register on a spreadsheet is an easy way to keep track of everything and see if there are any trends (e.g. more NCRs on a certain area, on a certain activity or even a team)

You could also track the following in regards to NCRs in Construction:

- Are NCRs getting closed in the agreed timeframe? (overdue NCRs is always a red flag on any project) – see also: How to Close NCRs in Construction

- Are NCRs raised and properly reported on time by the teams on site or are they just waiting for the Quality teams, the Senior Management or (even worse) the Client to discover them? (To be fair, that’s a difficult metric to measure and it really depends on the culture of the company and the project)

- Are NCRs raised on the same issue again and again? (this really shows that the corrective actions have not been implemented properly or not at all)

Overall, measuring and managing the NCRs in a construction project is an easy and straightforward way to report and get some statistics on things that have not gone right on the field. However, they might not give you the whole picture or they may even give you a distorted picture of what is actually happening in a construction project. The main reasons for this could be:

- NCRs are simply not reported at all because of a lack of proper quality culture in the company or the project overall. There is an infamous question among quality professionals in the construction industry: which one is of higher Quality? A project with thousands of NCRs or a project with none. I know for sure I wouldn’t trust a project with 0 NCRs, as it simply shows that nothing gets reported…

- There are many processes in a construction project that do not affect the final product directly and these could hide many inefficiencies and problems.

- NCRs usually do not provide info when things go out of budget and get delayed and everyone knows in Construction that money and time are the king and the queen of the industry.

- NCRs in general are an internal process (yes, the Client gets informed and involved in many cases in construction – especially in public infrastructure projects) and it does not provide information on how satisfied or not the Client is

And that’s why just measuring NCRs is never enough by itself to measure quality in construction projects.

2. Site Inspections and Materials Testing

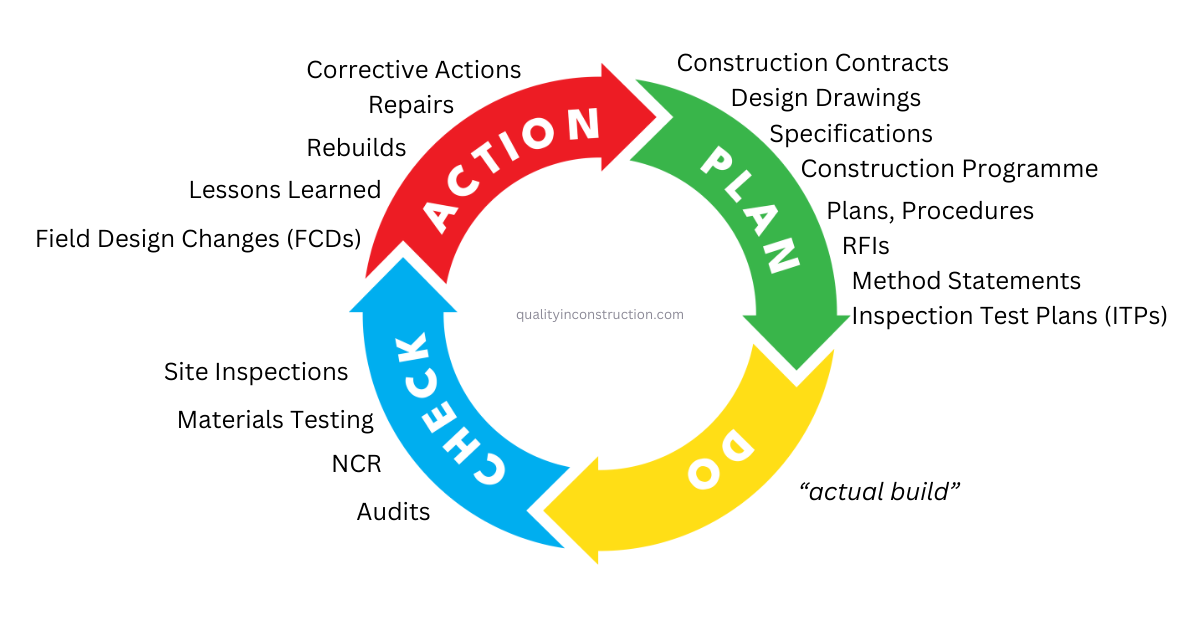

Testing materials on or off-site is an integral part of every construction project nowadays and it’s carried out as per an agreed and approved regime, which must be clearly dictated in a relevant Inspection and Test Plan (ITP).

The most obvious example of materials testing in a construction project, is the fresh or hardened concrete testing along with its statistical analysis from an accredited third-party laboratory.

But there are lots of other inspections and tests that take place in a construction site and basically measure conformity to the applicable design and specifications such as: ground testing, tube pressure testing, electrical testing, as-built surveys etc

Basically, every inspection and test that happens in a construction site is a measurement of conformity (or not).

Carrying out a statistical analysis on those inspections and ensuring that proper documentation and reports are kept, are very good indicators of whether things are going well (or not) quality-wise.

Sometimes, these inspections can be so important for the project that are called Hold Points, which basically means that any possible failure puts on hold the whole project.

3. Document Control Data (submissions, RFIs etc)

Submissions and the flow of documentation and data in a construction project is of the outmost criticality in modern construction management and modern Electronic Document Management Software has literally made our lives easier providing easy access to a wealth of reports.

The issuance, approval and final distribution of documentation is so critical nowadays that can literally be the cause of significant delays, penalties or budget derailments.

The following things can be measured in regards to Document Controlling in a construction project:

- Are documents submitted on time to allow the teams to prepare for the activity?

- Are documents revised quickly after the Client’s comments?

- How many times does a document need to be revised in order to get accepted by the Client?

- Are the final Issued-For-Construction Documents distributed to all the teams that need them on and off-site?

- Are RFIs and TQs answered on time?

- Are answers on RFIs taken into account in construction or are they actually forgotten?

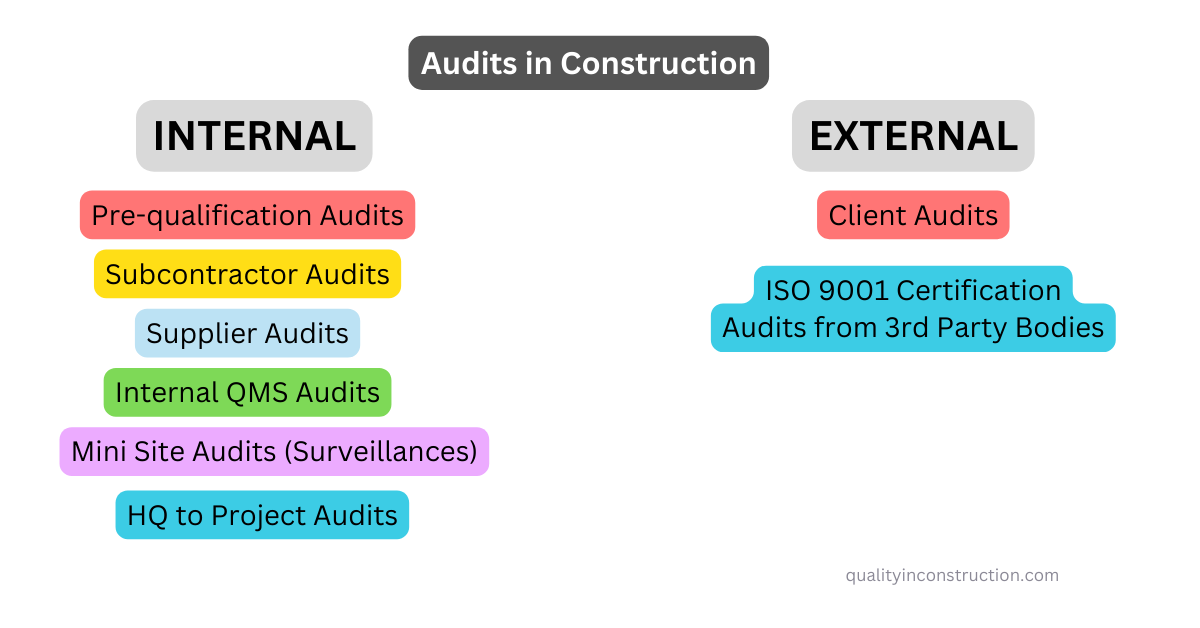

4. Data from Internal or External Audits

There is no doubt that a construction audit is an invaluable tool for measuring and monitoring the efficiency of the quality management along with the performance of external suppliers and subcontractors.

So, any data, nonconformancies and actions that occur after an internal or external audit provide extremely important information in regards to pretty much any process in a construction project and if scheduled and done properly can actually prevent any issues.

5. Handover Readiness and Completion

One of the most typical problems historically in the construction industry is the fact that nobody really cares to collect the paperwork for a certain activity or works, once these are taking place and when these are actually required at the end everyone runs like headless chickens to make sure reports are issued, checksheets are signed and as-built drawings prepared.

However, measuring how (and if) the handover documentation is in place, is an important factor that could actually determine the successful completion of a project. Usually, a simple spreadsheet with the breakdown structure of the project and a list of all the required handover documentation along with a monthly or weekly review with the relevant teams should be enough to keep everything in track.

6. Client Satisfaction Survey Data

In construction, it is actually quite easy to get and measure how satisfied your Client is.

You simply ask them!

It is true though that ertain people within a Client’s organization may have different opinions and views on how well a contractor or a subcontractor performs but a Client Satisfaction Survey with very targeted questions can be a good indicator of how things are going.

In my experience, these reviews and answers can be quite subjective sometimes depending on the person and the day…but they are nonetheless a documented expression of the Client’s satisfaction on a specific project.

Conclusion

Measuring Quality in a construction project is not something that can be done easily or without proper planning and preparation. As long as it is clear what the requirements are, there are specific tools such as NCRs, Document Control Metrics, Handover Readiness Trackers, Construction Audits Data and even Client Satisfaction Surveys that can provide valuable information in regards to how the quality management system of the project is performing and if continuous improvements is achieved.

However, because construction is a very challenging and unique environment to be measured and monitored properly, specific efforts must also be given to create a proper quality culture within the project that would eventually benefit all aspects of the Quality Management System, improve Client Satisfaction and final overall conformity to the agreed requirements and the design.

Very impressive and helpful.